INDUSTRIAL POWER DOMESTIC PRODUCTION

Growing Production Power with High Technology

YLB Automotive, which started its operations in 2011 with the production of plastic injection molds and parts, now manufactures with state-of-the-art machinery in a total closed area of 8,500 m² in Bursa OSB, following investments in 2023 and 2024. It provides high-quality and timely services to many sectors, especially the automotive industry.

Read More0+

m² PRODUCTION AREA0+

PRODUCTS0+

EMPLOYEES0+

EXPERIENCEQUALITY-FOCUSED AND INNOVATIVE

Quality is at the forefront of our principles, and every detail is meticulously examined. With our team that follows global trends, we have integrated the latest technology into our production.

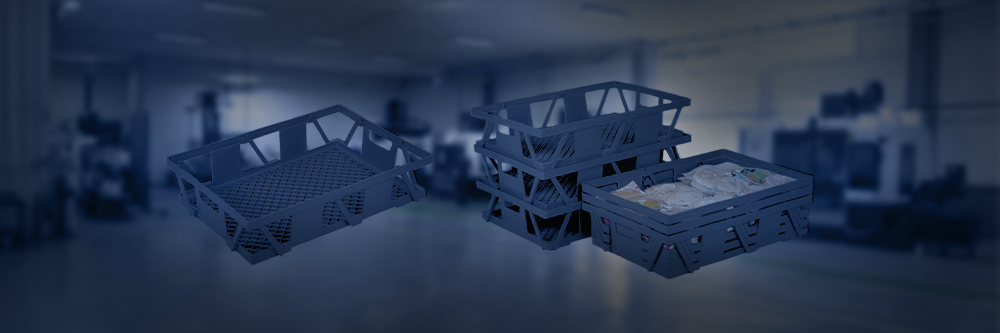

White Goods Part Production

YLB Automotive also contributes to the white goods sector with its carefully manufactured parts..

Plastic Injection

Offers fast, powerful, and innovative solutions in the plastic part manufacturing process with NX and VISI CAD/CAM/Analysis software.

Mold Manufacturing

Provides machining services for volume molding, tandem molds, fixtures, assembly apparatus, and industrial automation systems.

Automotive Part Production

Our specially designed parts guarantee high quality under the assurance of YLB Automotive.

Mold Manufacturing and Plastic Injection

YLB Automotive designs and manufactures high-precision plastic injection molds, and subsequently produces durable and high-quality plastic parts for various sectors, primarily automotive, using these molds.

INDUSTRIAL POWER

We blend quality with engineering in plastic injection and mold production, crowning the power of domestic manufacturing with global standards.

+90 224 504 80 08

+90 224 504 80 08 info@ylbautomotive.com

info@ylbautomotive.com